Hot Halves Can Be Fun For Everyone

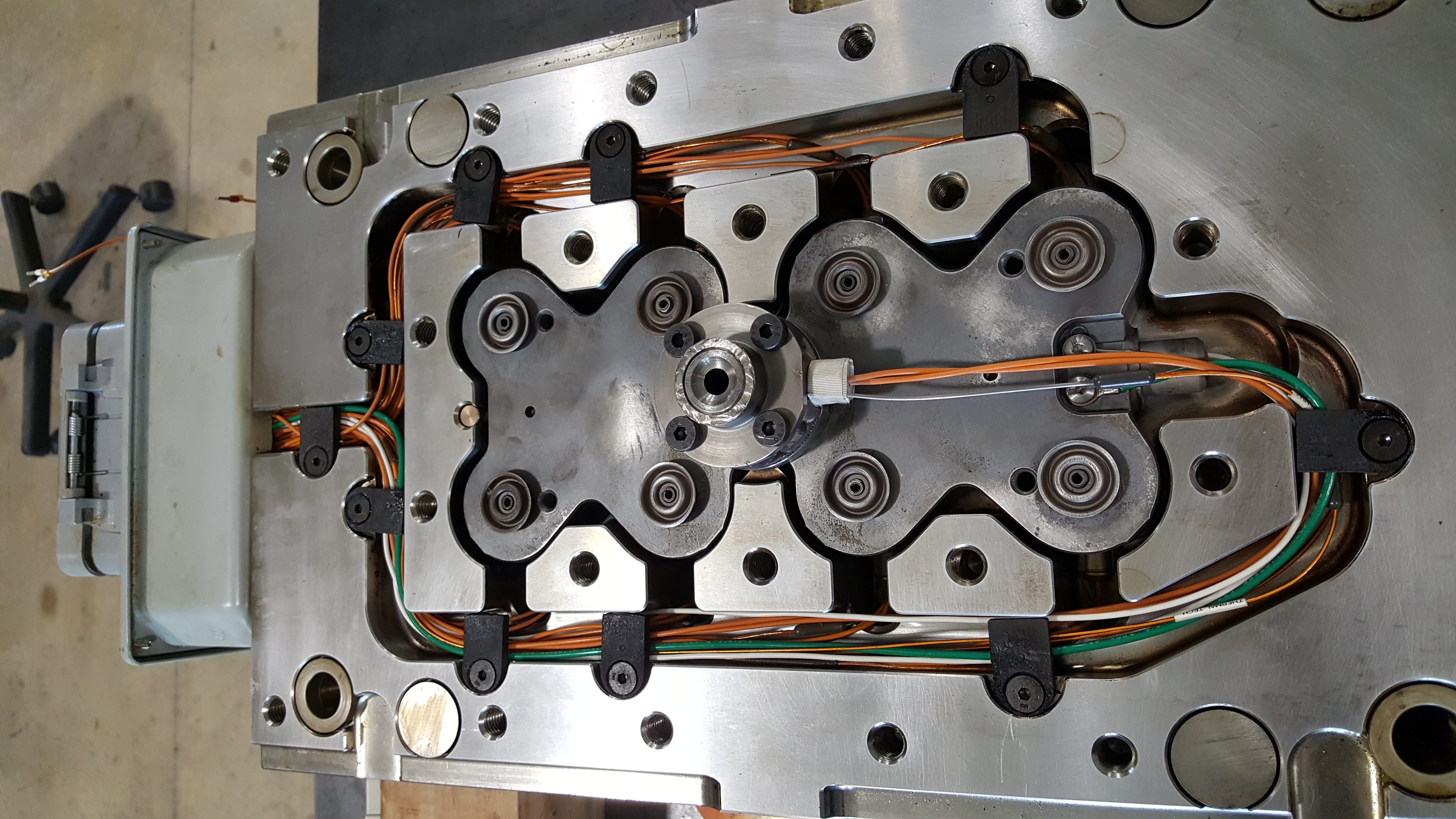

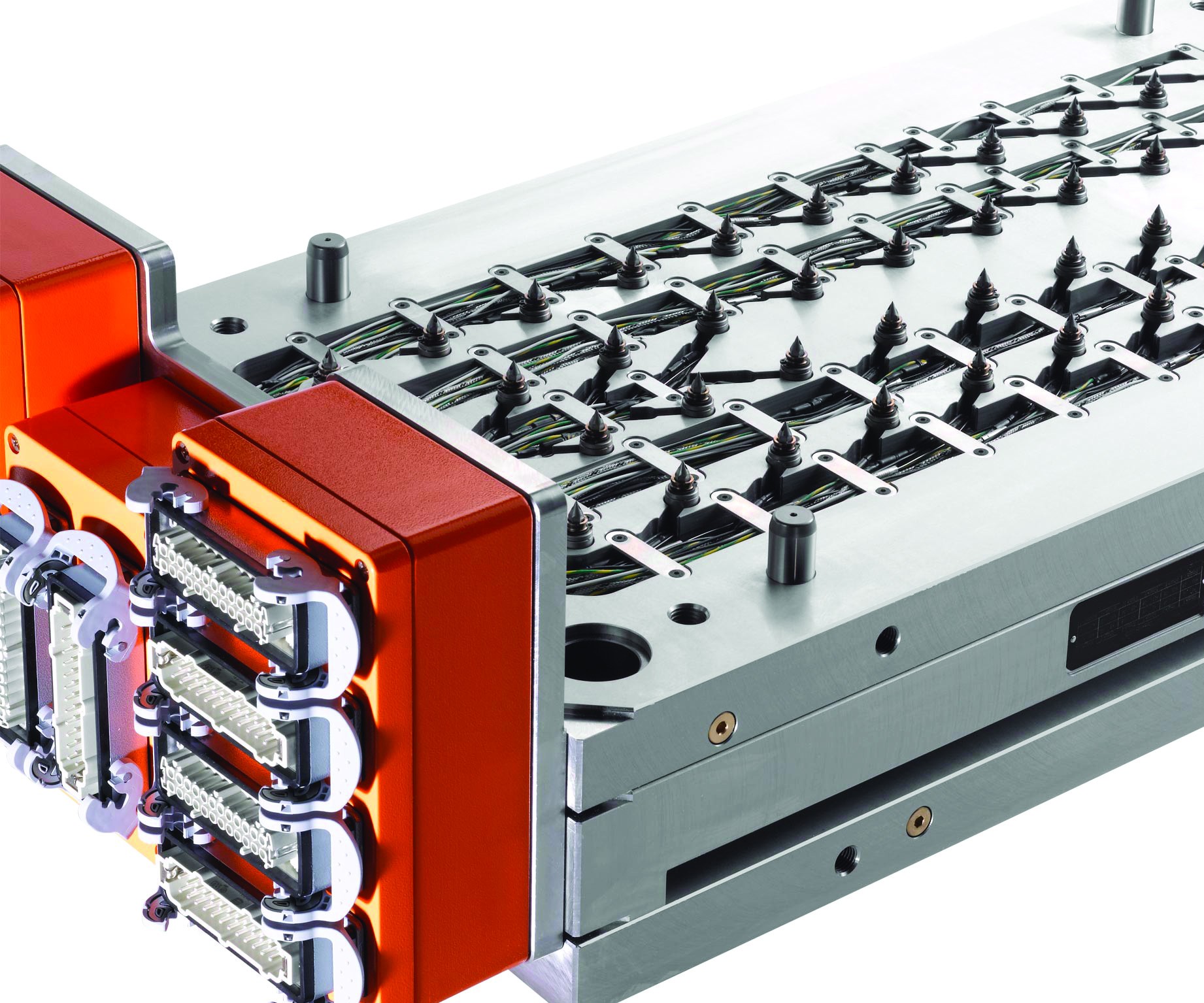

According to this 3rd element of the here and now development, a flow rotator for revolving a cross-sectional unbalanced problem of a laminar streaming product is given in a warm jogger system for providing a laminar moving material. The warm jogger system has (i) an upstream thaw flow, (ii) a pair of intermediary thaw passages downstream from the upstream thaw flow, and also (iii) for a minimum of one intermediary thaw flow, an involved pair of downstream melt flows downstream from the at the very least one intermediary melt flow.

SHORT DESCRIPTION OF THE ILLUSTRATIONS For a far better understanding of today creation and also to reveal more clearly how it may be carried right into impact, reference will now be made using instance to the coming with illustrations, showing articles made according to a preferred embodiment of the here and now creation, in which: FIG. hot halves.

1 b, in a schematic side view, shows a warm jogger manifold in conformity with the prior art; FIG. 2 is a view on A-A of FIG. 16; FIG. 3, in a sectional sight, illustrates the melt flow in a main runner of the hot runner manifold of FIG. 1 b as it branches into a pair of secondary runners; FIG.

16; FIG. 5, is a sight on C-C of FIG. 16; FIG. 6, in a sectional view, highlights the thaw flow of FIG. 4 as the additional jogger branches into a set of tertiary runners; FIG. 7, is a view on D-D on FIG. 1 b; FIG. 8, is a view on E-E of FIG.

9, is a sectional view on p-p of FIG. 10 a flow-rotating plug in conformity with a personification of the invention; FIG. 10, in a perspective sight, shows the flow-rotating plug of FIG. 8; FIG. 11 a, in a side view, illustrates a portion of a pile mold having the plug of FIG.

A Biased View of Hot Halves

23; FIG. 25, is a view on M-M of FIG. 23; FIG. 26, is a view on N-N of FIG. 23; FIG. 27, is a sight on O-O of FIG. 23; FIG. 28, in a schematic sight, illustrates a warm jogger system incorporating a supporting plug in accordance with a further facet of today invention; FIG - hot halves.

28; FIG. 30, is a sight on M ′-M ′- of FIG. 28; FIG. 31, is a view on N ′-N ′ of FIG. 28; and, FIG. 32, is a sight on O ′-O ′ of FIG. 30. IN-DEPTH DESCRIPTION OF THE CREATION Referring to FIG. 1 a, there is illustrated in a profile, a section of a stack injection molding device 10 in conformity with the prior art.

Hot Halves - Truths

The runner system 12 includes a key jogger 16 for getting melt from a melt source (not revealed). At an initial branch 18, the main runner 16 branches into 2 secondary runners 20. The secondary joggers 20, at respective 2nd branches 22, after that branch into tertiary runners 24. The tertiary joggers 24 supply thaw to connected nozzles 26, which inject the melt right into linked mold and mildew cavities (not revealed).

1 b, there is illustrated in a profile, a manifold 14 b of an injection molding apparatus 10 b in accordance with the prior art. The manifold 14 b includes a jogger system 12 b. The jogger system 12 b includes a main runner 16 b for obtaining melt from a thaw source (disappointed). FIGS. 2-8 are explained relative to the manifold 14 b just for simpleness. Describing FIG. 2, there is highlighted a sectional view of key runner 16 b at A-A of FIG. 1 b. A heated outer section 28 of the thaw around the jogger wall of the main runner 16 b is revealed by shielding.

2, the hotter thaw adjacent the runner wall surface is considerably consistently dispersed concerning the jogger wall. At the initial branch 18 b, the warmed peripheral part 28 of the circulation is divided into two, as received FIG. 3. hot halves. Each of these fifty percents of the warmed periphery after that flows into the additional joggers 20 b of the manifold 14 b.

check out here additional info moved here